Using a templated checklist for forklift inspection is a good idea for keeping your driver’s daily reviews on point. After all, it isn’t difficult to forget to check something if someone has had a rough morning.

Something as simple as a bad night’s sleep could lead drivers to forget to check an essential safety item. The solution is a streamlined, templated checklist for forklift inspection.

Any forklift operator should use a checklist for forklift inspection before operating the vehicle. Operators should complete the inspection process each day or shift, regardless of whom had previously operated the equipment.

Providing team members with an easy-to-use solution for their daily safety inspection makes everyone’s job easier. It also encourages safety awareness and safe working practices within your facility.

To aid your business in supporting a safe working environment, we’ve created a standardized checklist for forklift inspection that you can download right now for free. Let’s look at what we have included in this free downloadable template.

Table of Contents

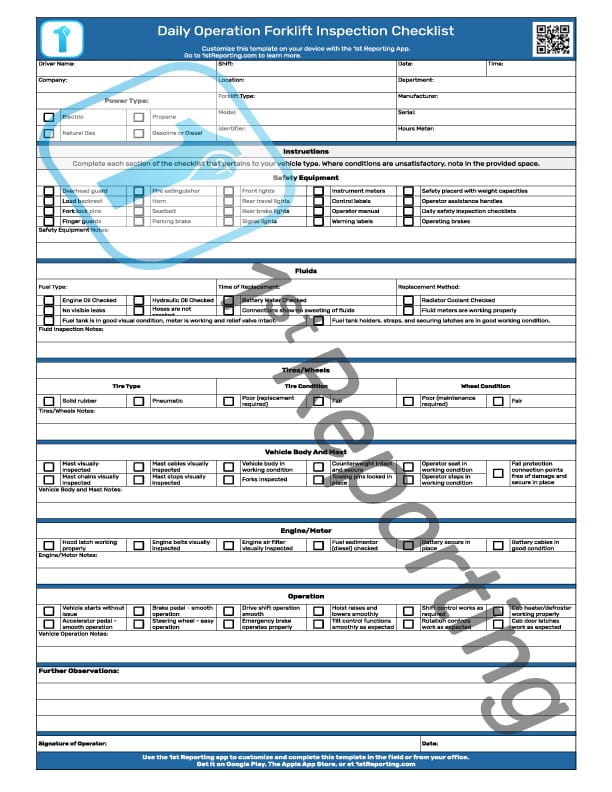

The checklist for forklift inspection includes many segments. Each segment consists of a brief description below to help you train your team members on each. Each component of the forklift inspection checklist includes two blank lines where the driver may make notes. These notes might have observed deficiencies observed during the inspection.

The administrative section of the forklift checklist is at the top of the inspection checklist. Although not labeled as the administrative section, you’ll notice the title suits it, given the type of information.

This information includes the name of the driver and the date. It also provides information about the company location, the forklift manufacturer, model, serial number, and even the power supply type.

Given that the point of the daily inspection of forklift equipment is primarily safety, the first checklist section of the inspection report focuses on safety. This daily forklift inspection checklist segment includes things like lighting, emergency brakes, and even fire extinguisher checks.

Fluids are the blood of any vehicle, and a forklift is no exception. Whether the forklift is internal combustion or electric, both will utilize vital fluids like brake, transmission, or even oil in the case of gas-burning engines.

Tires and wheels are the feet of our equipment and contact the ground. It is vital to inspect the tires and wheels to ensure the appropriate tread and conditions are provided. After all, so much is riding on your tires.

Most forklift vehicles have fairly heavy-duty bodies and seldom require body repairs if driven appropriately. However, there are several other physical factors essential to inspect. Furthermore, the mast requires inspection, which you can find in this segment of the checklist.

Engines within the internal combustion-powered forklifts require a more significant inspection assessment than an electric motor-powered forklift. Either way, both require a minimal inspection daily. The engine and motor segment of the checklist focuses on these systems.

The second-last of daily forklift inspection includes the operational testing of the equipment. This test ensures the proper and safe operation of the equipment. The driver may note any of their findings regarding vehicle operation in this segment of the forklift checklist.

The final section of the checklist includes a notes section and a sign-off area (with date). The note area allows your driver to note any further discrepancies with the equipment.

Let’s take a brief look at some of the best practices for using the checklist for daily forklift pre-operation safety inspections.

Using the checklist for forklift inspection couldn’t be easier. It’s simple; all you need to do is download our free template. Next, print off as many copies as you have forklifts.

Make a few extra copies to account for mistakes or vehicle and driver switches. You should now have enough inspection forms for one day of operation. Take the amount and print as many as you need for as many days as you require.

As you may have guessed, printing a month’s worth of forklift inspection checklists may be a big challenge. That is if you have a fleet of forklifts and multiple drivers. However, the checklist will work fine if you have only one or two forklifts and a similar number of drivers.

If you’re interested in increasing operational efficiency for your forklift inspections, take a look at the next section, where we’ll discuss some further tips and tricks you can use to make managing your fleet and drivers easier.

We’ve compiled nine of the best tips for managing your business forklift inspections. These tips will help you increase efficiency and make your inspection processes more cost-effective.

Keep the inspection checklist in the truck’s cab with the current date and information filled out for the last 30 days.

Keep a copy of each day’s inspection checklist for safe file management in your office. Maintaining a duplicate in safe office conditions ensures that your company is doing its due diligence to record safe working practices.

Having printed copies is essential if you have more than one driver or fleet of equipment. However, misplaced physical copies will mean additional time spent finding lost documents instead of completing a full inspection regimen. Consider using an organized filing system and checkpoints for drivers to hand in documents each day before driving the vehicle.

Ensure all drivers/operations managers understand how to use & follow the checklist guidelines. Try setting up an initial training event and then run semi-annual refreshers to ensure everyone is on board.

Increase Team Engagement. You can reduce all severe problems with oversight, regulatory compliance, and legal liability by engaging your employees in this checklist program. Communicate with them about what one expects of them and hold them accountable by following up with inspections throughout daily work life.

You get results when you set up an accountability system for employees to keep track of their performance and document non-compliant behavior. Not to say that an authoritarian way of managing is correct, but sometimes it is necessary and effective when relating to safety.

Most businesses don’t check on their employees often enough. Sometimes once a month or year will pass before someone catches a team member doing something out of line. However, these people are working close to dangerous equipment all day.

Using a document retrieval solution is essential for ensuring you have the necessary tools to have more efficient management processes in place. In addition, utilizing a checklist system can be especially helpful if you have multiple managers or supervisors responsible for carrying out inspections on equipment.

Utilize a reporting app (like the 1st Reporting app – checklist, audit, reporting, and inspection tool). Research and find the most suitable list for your business needs. There are many to choose from in the default template library. This library is built right into the app, so you have a great base to start for your business reporting.

You can record nearly anything within the app’s framework, from incidents to safety audits. You can even upload images and videos to reports so your team can include much more than is possible on a paper-printed report.

As the checklist information saves in your 1st Reporting account, you can access it from anywhere at any time. You don’t need to waste materials on printing reports every day. All of your checklist items are viewable and editable anytime with the app.

Many prefer apps over paper-printed sheets for one key reason: mobility. When you have a checklist or other manager tool at your fingertips, you reduce the time spent looking for documents and effectively concentrate on completing inspections.

There are many different types of inspection checklists available for various purposes. The customized checklist should suit your business needs because otherwise, it won’t be as effective. You can customize the list to match your company’s needs and save it in your account.

In addition, using a checklist app allows for notifications and reminders, so you don’t have to rely on manual checklist distribution to ensure inspections completion is timely and correct. You can set up custom notifications when any checklist procedure or protocol has not been met before allowing a driver/equipment fleet to operate.

For more information on having a custom digital checklist for forklift inspection, please visit our reporting solutions here.

The checklist we’ve provided here focuses on safety. And as a bonus, we’ve included nine tips for managers that can help optimize your daily inspections.

Forklift operators spend all day around heavy equipment and need constant supervision to ensure their safety and compliance with regulations.

With the 1st Reporting app (checklist, audit, reporting, and inspection tool), you can customize your list to suit your company’s needs while also having notifications about checklist procedures or protocols not being met before allowing drivers/fleets of equipment into service. Download it today!